How Electric Dryer Parts & Components Work Part 2

This page provides a description as well as simple testing methods for each of the parts and components related to an electric dryer. All tests should be preformed with the dryer unplugged and all wires connected to the part being tested unplugged.

(Note: Label all terminals and connecting wires before disconnecting them for proper reinstallation.)

Click Here For Gas Dryer Parts & Troubleshooting Help

Start Switch:

The dryer's start switch is a momentary contact push switch that allows electricity to energize the motor. Once the motor has begun to spin, an expanding contact within the motor, called a centrifugal switch, expands to maintain contact after the start switch has been released. Some models that have a "finish guard" or "wrinkle prevent" option will automatically start the dryer from time to time after the dry cycle has ended to prevent the clothes within the dryer drum from becoming wrinkled. These start switches have an internal solenoid to activate the switch automatically without it needing to be manually pushed. This style of dryer start switch will have three contacts instead of two.

Test: How-To Test A Clothes Dryer Start Switch Videos.

Remove all connected wires and check for continuity across the two main terminals. While pressing the switch, there should be no resistance measured (a closed circuit, allowing electricity to flow). Three-wire dryer start switches can be checked in the same way. Look at your wire diagram or a chart on the switch for test points. The switch itself can be described in the same way as the above style, but the secondary coil contacts should give some resistance to activate the switch.

Timer:

The dryer's timer routes electricity to the correct dryer components or system at the proper time. Timers are expensive, rarely fail, and are often misdiagnosed. The timer should be allowing electricity to flow to the dryer's heating element and motor when needed.

Test: Use your dryer's wiring diagram to check for voltage being supplied to the heating circuit or motor circuit.

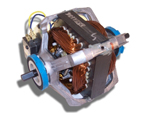

Motor:

The dryer motor is used to create the circular motion required to turn the dryer drum and blower. The dryer motor also completes an electrical circuit. Once the motor has begun to spin, an expanding contact within the motor called a centrifugal switch expands to maintain contact after the start switch has been released.

The dryer motor is used to create the circular motion required to turn the dryer drum and blower. The dryer motor also completes an electrical circuit. Once the motor has begun to spin, an expanding contact within the motor called a centrifugal switch expands to maintain contact after the start switch has been released.

Test: A motor can be checked for resistance across the start windings and main windings. The proper resistance levels and test points can often be found in your dryer's wire diagram. In some cases a large amount of lint can collect on the motor causing it to over-heat. In other cases the contacts to the motor may become loose and not allow electricity to enter or leave the motor circuit. This can cause the motor to not run or other components to not work properly. If you have a "dead" motor you should also check the door switch, belt switch (some models), and timer before replacing the motor.

Back to Top

Temperature Selection Switch:

A clothes dryer's temperature selection switch is a simple switch that will send electrical current to the thermostat heater through resistors. Resistors are usually located on the wires connecting to the switch, but sometimes within the switch itself depending on your model. In this way the amount of current reaching the dryer's thermostat heater is controlled. Some dryer models will use a thermistor and a separate solid-state control board to regulate the dryer's drum temperature. The dryer's temperature selection switch rarely fails.

Test: Disconnect all connecting wires and check for continuity across the switch and all wire harness resistors. If you have a solid-state control board, visually inspect it for burn marks. Use your dryer's wiring diagram for more accurate testing.

Heating Element:

A heating element is used in electric dryers to generate the heat needed to dry your clothes. Almost all heating elements require 240 Volts to function correctly. Sometimes the heating element can short, allowing contact to ground. If this does not trip the circuit breaker, it will effectively bypass the cycling thermostat and cause the heater to never cycle off as long as the dryer is running.

A heating element is used in electric dryers to generate the heat needed to dry your clothes. Almost all heating elements require 240 Volts to function correctly. Sometimes the heating element can short, allowing contact to ground. If this does not trip the circuit breaker, it will effectively bypass the cycling thermostat and cause the heater to never cycle off as long as the dryer is running.

Test: How-To Test A Clothes Dryer Heating Element Video.

Remove all connecting wires and check for resistance across the two terminals of the heater. Some resistance should be detected allowing the heater to perform its work. If an open circuit is detected, the heater needs to be replaced. Also check each of the heater's contacts to the outer containment unit of the heating element. There should be no connection. If the heater tests okay, check the connected thermostats for continuity and your home's power supply for full 240-volt supply.

Blower:

Dryers use a blower wheel to move air across the dryer's heat source and through the dryer's drum. Airflow is extremely important for a dryer to operate properly. Air that is  saturated with evaporated water must be removed from the dryer's drum for more evaporation to occur. Not all blower wheels are the same, even though they all perform the same function. Fast clicking or buzzing noises are often an indicator that some object is grinding against the blower wheel as it turns. In some cases the blower's connection to the motor shaft may weaken, causing the blower to rattle and shake, especially when you first open the door to stop the dryer. This can also reduce the speed at which the blower spins, cutting airflow and increasing the time required to dry a load of clothes.

saturated with evaporated water must be removed from the dryer's drum for more evaporation to occur. Not all blower wheels are the same, even though they all perform the same function. Fast clicking or buzzing noises are often an indicator that some object is grinding against the blower wheel as it turns. In some cases the blower's connection to the motor shaft may weaken, causing the blower to rattle and shake, especially when you first open the door to stop the dryer. This can also reduce the speed at which the blower spins, cutting airflow and increasing the time required to dry a load of clothes.

How-to Replace Dryer Blower Wheel Videos

Belt:

The belt transfers the power generated by the motor to the drum, enabling it to tumble. Belt sizes and styles are model specific.

Test: Physically inspect the belt for signs of cracking or burning.

Dryer Belt Installation Help By Brand

Back to Top

More