Dryer Repair

Gas Dryer Won’t Start or Dryer Noise

Thermal Fuse | Start Switch| Timer | Motor | Temperature Switch | Blower | Belt | Belt Switch| Door Switch | Drum Bearing | Belt Pulley | Drum Support | Air Flow | Dryer Noises

Gas Dryer Repair – Possible causes

“Gas Dryer won’t start” or “Gas Dryer won’t turn on.”

Gas Dryer Thermal Fuse:

The dryer’s thermal fuse is a non-resettable safety fuse that is designed to break electrical contact to the dryer’s burner if the dryer becomes too hot. This fuse will often burn out due to clogged dryer ducting or a defective cycling thermostat. The thermal fuse is the most common cause when a dryer has no heat.

The dryer’s thermal fuse is a non-resettable safety fuse that is designed to break electrical contact to the dryer’s burner if the dryer becomes too hot. This fuse will often burn out due to clogged dryer ducting or a defective cycling thermostat. The thermal fuse is the most common cause when a dryer has no heat.

Dryer Symptoms: On a gas dryer the dryer will not start. However, in electric dryers, the dryer won’t heat.

Test: How-To Test A Dryer Fuse Videos.

Disconnect all connecting wires and check for continuity across the two wire contacts. There should be no resistance measured (a closed circuit, allowing electricity to flow).

Gas Dryer Start Switch:

The dryer’s start switch is a momentary contact push switch that allows electricity to energize the motor. Once the motor has begun to spin, an expanding contact within the motor, called a centrifugal switch, expands to maintain contact after the start switch has been released. Some models that have a “finish guard” or “wrinkle prevent” option will automatically start the dryer from time to time after the dry cycle has ended to prevent the clothes within the dryer drum from becoming wrinkled. These start switches have an internal solenoid to activate the switch automatically without it needing to be manually pushed. This style of dryer start switch will have three or four contacts instead of two.

Dryer Symptoms: The dryer won’t start.

Test: How-To Test A Clothes Dryer Start Switch Video.

Remove all connected wires and check for continuity across the two main terminals. While pressing the switch, there should be no resistance measured (a closed circuit, allowing electricity to flow). Three-wire dryer start switches can be checked in the same way. Look at your wire diagram or a chart on the switch for test points. The switch itself can be described in the same way as the above style, but the secondary coil contacts should give some resistance to activate the switch.

The dryer’s timer routes electricity to the correct dryer components or system at the proper time. Timers are expensive, rarely fail, and are often misdiagnosed. The timer should be allowing electricity to flow to the dryer’s burner and motor when needed.

Test: Use your dryer’s wiring diagram to check for voltage being supplied to the heating circuit or motor circuit.

Door Switch:

The dryer’s door switch senses if the door is open or closed. When the door is closed the switch will close, allowing power to circulate through the rest of the circuit. When the dryer door is open the switch will open, breaking electrical contact to the neutral connection of the circuit and stopping the flow of electricity. Some door switches are “single pole double throw” meaning that when the door is opened the dryer’s main component circuit is open, but the dryer’s drum light is energized. Most often the actuator arm of this switch will physically break off. However, sometimes the switch will break internally with no external indicators.

The dryer’s door switch senses if the door is open or closed. When the door is closed the switch will close, allowing power to circulate through the rest of the circuit. When the dryer door is open the switch will open, breaking electrical contact to the neutral connection of the circuit and stopping the flow of electricity. Some door switches are “single pole double throw” meaning that when the door is opened the dryer’s main component circuit is open, but the dryer’s drum light is energized. Most often the actuator arm of this switch will physically break off. However, sometimes the switch will break internally with no external indicators.

Dryer Symptoms: The dryer won’t start.

Test: How-To Test A Dryer Door Switch Video.

Remove all connecting wires and check for continuity across the switch’s primary component circuit. There should be no resistance measured (a closed circuit, allowing electricity to flow).

Gas Dryer Motor:

The dryer motor is used to turn the dryer drum and blower. The dryer motor also completes an electrical circuit. Once the motor has begun to spin, an expanding contact within the motor called a centrifugal switch expands to maintain contact after the start switch has been released.

The dryer motor is used to turn the dryer drum and blower. The dryer motor also completes an electrical circuit. Once the motor has begun to spin, an expanding contact within the motor called a centrifugal switch expands to maintain contact after the start switch has been released.

Dryer Symptoms: The dryer won’t start or will stop and only start after cooling down.

Test: A motor can be checked for resistance across the start windings and main windings. The proper resistance levels and test points can often be found in your dryer’s wire diagram. In some cases, a large amount of lint can collect on the motor causing it to overheat. In other cases, the contacts to the motor may become loose and not allow electricity to enter or leave the motor circuit. This can cause the motor not to run or other components to not work properly. If you have a “dead” motor, you should also check the door switch, belt switch (some models), and timer before replacing the motor.

Gas Dryer Repair – Possible causes

“Gas Dryer Noises”

[/vc_column_text][/vc_column][/vc_row]Gas Dryer Blower:

Dryers use a blower wheel to move air across the dryer’s heat source and through the dryer’s drum. Airflow is extremely important for a dryer to operate properly. Air that is saturated with evaporated water must be removed from the dryer’s drum for more evaporation to occur. Not all blower wheels are the same, even though they all perform the same function. Fast clicking or buzzing noises are often an indicator that some object is grinding against the blower wheel as it turns. In some cases the blower’s connection to the motor shaft may weaken, causing the blower to rattle and shake, especially when you first open the door to stop the dryer. This can also reduce the speed at which the blower spins, cutting airflow and increasing the time required to dry a load of clothes.

Dryers use a blower wheel to move air across the dryer’s heat source and through the dryer’s drum. Airflow is extremely important for a dryer to operate properly. Air that is saturated with evaporated water must be removed from the dryer’s drum for more evaporation to occur. Not all blower wheels are the same, even though they all perform the same function. Fast clicking or buzzing noises are often an indicator that some object is grinding against the blower wheel as it turns. In some cases the blower’s connection to the motor shaft may weaken, causing the blower to rattle and shake, especially when you first open the door to stop the dryer. This can also reduce the speed at which the blower spins, cutting airflow and increasing the time required to dry a load of clothes.

How-to Replace Dryer Blower Wheel Videos

Belt:

The belt transfers the power generated by the motor to the drum, enabling it to tumble. Belt sizes and styles are model specific.

Dryer Symptoms: The dryer won’t start or will run but not tumble.

Test: Physically inspect the belt for signs of cracking or burning.

Dryer Belt Installation Help By Brand

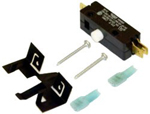

Belt Switch:

Some dryer models use a belt switch attached to the belt tension pulley, which will open if the dryer’s belt breaks, not allowing the dryer to operate. Symptoms of a broken belt are similar to that of a broken door switch. The dryer will not start or stops suddenly in the middle of a dry cycle.

Dryer Symptoms: The dryer won’t start.

Test: How-To Test A Clothes Dryer Belt Switch Videos.

Remove all connecting wires to the belt switch and test for continuity across the switch terminals. There should be no resistance measured (a closed circuit, allowing electricity to flow).

Belt Tension Pulley:

The belt pulley (also called the idler pulley) keeps tension on the belt, creating the small amount of friction necessary for the belt to grip the motor and the drum. Dryer manufacturers have used a variety of belts and pulley designs through the years. Most methods of belt/pulley installation can be found on the dryer pulley installation page. The tension pulley can be responsible for some squeaking noises as well as causing the belt to burn. Other possible causes of these same symptoms could be drum supports or any component that would make it difficult for the drum to rotate freely.

amount of friction necessary for the belt to grip the motor and the drum. Dryer manufacturers have used a variety of belts and pulley designs through the years. Most methods of belt/pulley installation can be found on the dryer pulley installation page. The tension pulley can be responsible for some squeaking noises as well as causing the belt to burn. Other possible causes of these same symptoms could be drum supports or any component that would make it difficult for the drum to rotate freely.

Dryer Symptoms: The dryer will squeak, sometimes leading to dryer won’t start if the dryer belt breaks.

The dryer’s drum can be supported by several methods. Some dryers use a rear drum bearing to support the weight of the dryer drum and wet clothing. Others use nylon or felt to pad the contact points between the dryer’s moving and stationary parts. These bearings can wear out and cause squeaking and scraping noises. In extreme cases, where loud dryer noises have been ignored for extended periods of time, the motor may no longer be able to turn the drum, and a humming sound will replace the grinding. Allowing grinding and squeaking noises to continue without repair can significantly increase the cost of repair.

Dryer Symptoms: The dryer will make a squeaking or grinding noise.

Drum Support:

Dryers use several different methods and components to support the drum and allow it to rotate with ease. Most designs have a series of rollers that hold the drum in position and a felt material that reduces friction and creates a light air seal for proper airflow. Some manufacturers, such as General Electric and Frigidaire, use a single ball bearing that is mounted to the back of the dryer drum. This bearing turns within a lubricated nylon cradle mounted to the dryer’s stationary rear bulkhead. Some dryer models simply have pads that resist friction to support the drum and allow rotation. Any of these supporting methods can wear out over time and cause squeaking and grinding noises.

Dryers use several different methods and components to support the drum and allow it to rotate with ease. Most designs have a series of rollers that hold the drum in position and a felt material that reduces friction and creates a light air seal for proper airflow. Some manufacturers, such as General Electric and Frigidaire, use a single ball bearing that is mounted to the back of the dryer drum. This bearing turns within a lubricated nylon cradle mounted to the dryer’s stationary rear bulkhead. Some dryer models simply have pads that resist friction to support the drum and allow rotation. Any of these supporting methods can wear out over time and cause squeaking and grinding noises.

Dryer Symptoms: The dryer squeaking or other dryer noise.

Test: Visual inspection of all points of contact between the moving drum and fixed points is the best way to determine if one or more components need replacement.